Who We Are

KBE is a leading manufacturer of air movement & fire smoke management products, dedicated to providing the best service for the HVAC market. Found...

Mission & Vision

Our Mission As a pioneer in this industry, our mission is dedicated to making continuous improvements to provide high-performing and high-standard air...

Featured Products

MODEL LFB (HT,JT and LT)

APPLICATION

Flow Bar systems satisfy both the architect's and the engineer's requirements for air distribution system that will maintain optimum room air conditions. The KBE Flow Bar linear system is a continuous slot system which allows the air distribution while being fully integrated within the ceiling system and its components.

STANDARD CONSTRUCTION

•Frame:

-Constructed of extruded aluminum alloy 6063-T5

• Flanged Fixed Frame (FF) with Angle end cap

• Frame Partition:

- Constructed of extruded aluminum alloy 6063-T5

• Deflectors:

- Constructed of extruded aluminum alloy 6063-T5

- Deflectors color: Black

- The fully adjustable deflectors allow for air pattern to be controlled from vertical straight down to horizontal along the ceiling.

• Sizes:

- Standard slot sizes are 1, 1¹/₂" , 2" , 2¹/₂" , 3".

- Minimum length of 8”.

- Length up to 114” full section. Multi-Sections are joined with alignment strips for continuous appearance.

• Number of slots: 1 or 2

- For V-shape only 1 slot .

• Finish:

- Standard finish is white color ( RAL 9010) for face of the diffuser & black (RAL 9005) for the deflectors.

OPTIONS

1.Frame Type:

- Removable (RF) or Frameless (F0) or V-shape hidden frame (VF) or (EF) Embedded hidden frame under spackling paste.

2.End Cap Configuration:

- Angle end cap (Standard for Fixed frame (FF), Removable frame (RF) & Embedded frame (EF))

- Flush end cap (Standard for V-shaped (VF) and frameless (F0) frame type)

- Mitered end cap (applicable for all frames except for V-shaped frame (VF) type)

- Open end cap

3.Throw Type:

- High Throw: for ceiling & wall application.

- Jet Throw: for wall application.

- Long Throw: for ceiling & wall application.

4.Accessories:

- LS Light Shield

- FC field cut

- BO metal blank-off

- Bracket applicable for Fixed Frame (FF), Removable Frame (RF), Embedded Frame (EF) & Frameless (F0).

- Clips applicable for V-shaped (VF) (STD) & Frameless (F0) (STD).

5.Corners & Curved:

- Mitered corner for ceiling & wall application.

- Curved for ceiling & wall application.

6. Other color available upon request.

7. Plenum box - insulated or non-insulated.

SLSD-TH

APPLICATION

The SLSD-TH series supply & return linear slot diffusers offer high performance in a VAV outlet with pattern control and complete blank-off true design flexibility.

Designed for efficient air distribution at cooling differentials up to 30°F.

FEATURED STANDARD CONSTRUCTION

SLSD-TH with deflector & damper as supply linear slot diffuser.

• FRAME:

- Constructed from extruded aluminum alloy 6063-T5 of 1.2 mm thickness.

• Surface/Flush mounting - Wide border.

•Angle end cap is provided.

• FRAME PARTITION:

- Constructed from extruded aluminum alloy 6063-T5 of 1.2 mm thickness.

• FIXED & SLIDING DAMPER:

- Constructed of aluminum sheet of 0.5 mm thickness of ¾” & 1” slot spacing.

- By offseting the holes, the airflow rate can be reduced or can even work as blank off for dummy parts.

- Damper works also as equalizing grid.

- Damper color : Black.

- The sliding damper controls the distribution of the airflow.

• DEFLECTORS:

- The fully adjustable deflection blades allow for air pattern to be controlled from vertical straight down to horizontal along the ceiling.

• SIZES:

- Minimum length of 8”

- Length up to 114” full section for slot number between 1 and 6.

- Length up to 80” full section for slot number greater than or equal to 7.

- Multi-sections are joined with alignment strips for continuous appearance.

• FINISHING:

- Standard finish is white color ( RAL 9010 ) for frame, frame partition and blades.

- Join strip provided for continuous slots.

OPTIONS

• Frame is available in surface, lay-in T-bar & narrow borders.

• Insulated or non-insulated plenum box.

• Mounting Bracket.

• Open end, Flush end & Mitered cap are available.

• Mitered corner for ceiling & wall application ( 90° angle or any special angle ).

• Curved for ceiling application.

• FC field cut.

• BO metal blank-off.

• LS light shield.

• Alignment strips.

• D: with damper w/o deflector (return).

• DF: with deflector w/o damper (return).

• W/O damper nor deflector (return).

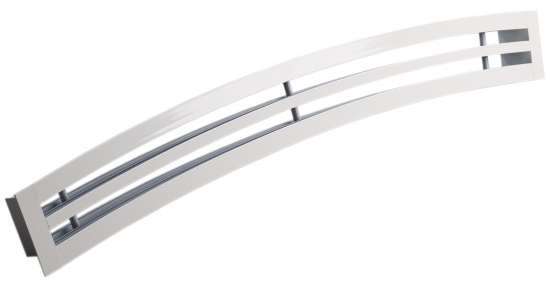

LBD

APPLICATION

KBE extruded aluminum linear bar diffusers meet architectural demands for a versatile supply and return air duct that blends with accents linear design concepts.

Linear Bar Diffusers can be used on the supply or return positions of heating, cooling or ventilating system. Linear bar diffusers are made of high grade aluminum extrusions for maximum strength and corrosion resistance. Ideal for sidewall, sill or ceiling installation.

FEATURED STANDARD CONSTRUCTION

•FRAME:

- Constructed of extruded aluminum.

- Interlocked into heavy gauge cross bars to produce straight rigid core sections.

•BLADES:

- Constructed of extruded aluminum.

- Multiple angles of deflection.(0º, 15º and 30º) placed on either 1/4" (6.35mm) & 1/2" (12.5mm) centers.

•SIZES:

- Minimum length of 8" and 2" height.

- Length up to 114" full section for openings between 2" and 8". Multi-sections are joined with alignment strips

for continuous appearance.

- Length up to 96" full section for 9" openings. Multi-sections are joined with alignment strips for

continuous appearance.

- Length up to 80" full section for openings between 10" and 12". Multi-section are joined with

alignment strips for continuous appearance.

•FINISH:

- Standard finish is white color (RAL 9010).

OPTIONS

• 2cm frame, 3cm frame, removable core, frameless.

• Mitered corner for ceiling & wall application (90° angle or any special angle).

• Curved for ceiling and wall applications.

• Other colors available upon request.

• Plenum box - insulated or non-insulated.

• With S-spring clips (except for frameless & removable core models).

• With foam gasket (except for frameless & removable core models).

• With opposed blade damper (for a minimum height of 3"& a minimum length of 8").

• Equalizing grid.

• BO metal blank-off black color (Ral 9005).

• LS light shield black color (Ral 9005).

• Insect screen.

N.B: A 0.5 cm clearance is deducted from your order neck size.

- For corner edge (wall) a drawing showing the airflow should be provided.

KFSD-111 Class I

APPLICATION

MODEL KFSD-111 is a UL 555 & UL555S Classified combination fire smoke damper used in dynamic smoke management system and to be used in partitions with fire resistance ratings of less than 3 hours.

Operation & Dynamic closure for Vertical & Horizontal mount with airflow on both sides rated:

- Max Static Pressure: up to 4” W.G (1000Pa)

- Max Velocity: up to 4000 FPM (20.3m/s).

- Operating Temp: up to 350°F (177°C).

STANDARD CONSTRUCTION

• FRAME

16 gauge (1.6mm) galvanized steel interlocking hat section channel frame construction.

• BLADES

16 gauge (1.6mm) galvanized 3 "V" formed.

• CLOSURE DEVICE.

Electronic Fusible link RS-100 with closure temperature of 165° F (74°C) (others available)

• BEARINGS

Sintered bronze, oil impregnated.

• AXLES

1/2" (12.7mm) square zinc plated steel studs.

• LINKAGE

0.12 x 0.50 (3x12.7mm) zinc plated steel concealed in the channel frame.

• FINISH

Mill galvanized.

• BLADES SEALS

Silicone edge type for smoke seal to 450°F (232°C)

• JAMB SEALS

300 Series stainless steel, flexible metal compression type.

• JACK SHAFT

1/2”(12.7mm) diameter zinc plated steel with jack-shaft connector coupling.

• ACTUATOR

Electric spring return 230V, 120V or 24V and pneumatic.

• CAULKING

UL approved silicone sealants: Dow Corning RTV-732, Nuflex 302.

• SLEEVES

Rectangular.

MINIMUM SIZE Single Section

8" (203mm) Width x 8" (203mm) Height.

MAXIMUM SIZE Single Section

36" (914mm) Width x 36"(914mm) Height.

FEATURES

*Each damper is marked with a UL555 & UL555S Classified fire Smoke damper label for use in Dynamic system.

*Meets NFPA 90A, 92A&B criteria for primary fire smoke dampers in walls and floors with fire resistance ratings of less than 3 hours.

OPTIONS

• CLOSURE DEVICE: RS-200, FUSIBLE LINK, RL.

• BEARINGS: Stainless steel.

• ACTUATOR MOUNTING: External & internal.

• OPTIONAL MATERIAL: Stainless steel construction.

• SLEEVES: Round, oval and specials.

NOTES

*Dampers furnished approximately 1/4" (6mm) smaller than given duct dimension

*Refer to the KBE Installation Instruction and supplements for complete installation details.

K75-B

APPLICATION

Model K75 is approved for use in walls, floors and partitions with fire resistance ratings less than 3 hours.

STANDARD CONSTRUCTION

• FRAME.

4-1/4" (108mm) Maximum X 22 (0.85mm) gauge

Galvanized steel channel.

• BLADES.

22 (0.85mm) gauge Galvanized steel curtain type out of the air stream.

• FINISH.

Mill.

• CLOSURE SPRINGS.

301 Stainless Steel Spring. (For Horizontal mount only, optional on vertical mount)

• FUSIBLE LINK.

Standard 165° F ( 74° C). Other available.

• MOUNTING.

Vertical or Horizontal .

• MINIMUM SIZE.

Vertical & Horizontal Installation:

4"Wx 4"H (100 x100mm).

• MAXIMUM SIZE.

Single Section Vertical & Horizontal Installation:

60"Wx 53"H (1520 x 1350mm).

• Multiple Section Vertical Installation:

120"Wx 120"H (3050 x 3050mm).

• Multiple Section Horizontal Installation:

68"Wx 96"H. (1730 x 2440mm).

FEATURES

*Each damper is marked with a 1-1/2 hours UL 555

Classified fire damper label.

*Meets all UL and NFPA criteria for primary fire dampers in walls and floors with fire resistance ratings of less than 3 hours.

VARIATION

All UL Classified fire dampers must be fabricated in accordance with UL procedures. Available variation are limited to those incorporated in the approved procedures.

Approved variations available at additional cost are :

*Factory furnished sleeves.

Sleeves are available in 10 (3mm) through 20 (1mm) gauge steel and in lengths required for the specific application.

NOTES

* Dampers furnished approximately 1/4"(6mm) smaller than given duct dimension

* Refer to the KBE Installation Instruction and supplements for complete installation details.

MODEL LFD-LFDW

APPLICATION

LFD model is designed to be used in clean space environments such as medical facilities (pharmaceutical / biotechnology industry), research industries (semiconductors, aerospace industries), hospital operating and clean rooms.

LFD have low aspiration characteristics resulting in rapid temperature and velocity equalization of air mass into the zone of occupancy.

FEATURED STANDARD CONSTRUCTION

• OUTER FRAME:

- Constructed from 20 Ga galvanized steel sheets with punched corners.

• FACE:

- Constructed from 4 mm hole diameter perforated galvanized steel sheets.

• FILTER FIXATION:

- Normal Steel Clamp.

• SIZES:

- Available sizes are: 24” x 24” or 600mm x 600mm

36” x 24” or 900mm x 600mm

48” x 24” or 1200mm x 600mm

• FINISH:

- RAL 9010 White Finish.

OPTIONS

• 16 Ga Galvanized Steel construction.

• 1 and 1.5 mm Stainless Steel 304 construction.

• 1 and 1.5 mm Stainless Steel 316 construction.

• 1 and 1.5 mm Aluminum construction.

• Aluminum, Stainless Steel 304 and Stainless Steel 316 perforated sheets for the face.

• 3 cm extruded Aluminum flange for Aluminum and Galvanized construction for T-bar mount.

• 3 cm Stainless Steel duct flange for Stainless Steel construction for T-bar mount.

• HEPA filter H13 (99.95% degree of arrestance) or H14 (99.995% degree of arrestance) grade.

• Stainless Steel handle for filter fixation.

N.B: A 0.5 cm clearance is deducted from your order size.

For more information please consult our engineers.

Tests Conducted in accordance with ASHRAE Standard 70-2006 in ETL-ETS USA

Leakage tests were conducted in accordance with AMCA Standard 500-D-2012 entitled, “Laboratory Methods for Testing Dampers for Rating” ETL-ETS USA.

Distributor For

FIRE RATED COATING FOR DUCTS (FIRESPRAY)

DUCT HEATER (INDEECO)

Trench Heaters, Wall-Mounted convectors, Free-standing Convectors (MINIB)

HVAC Solutions for operating Theatres

SMOKE VENT (BACH)

Smoke and Fire Curtain (U.S. Smoke & Fire)

Architectural diffusers (EffectiV)

FIRESTOP SELF-SEAL (NUCO Inc.)

AIR CURTAIN

CONSTANT AIR VOLUME DAMPER (AEROTECHNIK)

Electric Heaters (Brasch Manufacturing)

Antibacterial air distribution (Tecnica)

EN Fire Damper

Marine fire damper

Inertial Filter